EWTA members are typically recognized at the APA Annual Meeting and EWTA Info Fair for innovative practices and excellence in service.

Following are the entries for the 2021 Innovation of the Year Award.

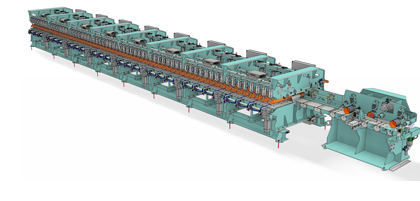

The Belt Conveyor

The Belt Conveyor

Entered By: Bruks Siwertell

Date of First Use: Q1 2021

Benefit 1: Air-supported belt conveyor has a totally enclosed design that protects the environment from dust emissions and reduces any material losses to a minimum.

Benefit 2: Reduced maintenance and operating costs

Results: We have innovatively combined the use of air-cushion technology with our standard belt conveyors to create The Belt Conveyor, offering our customers a high-capacity, completely enclosed conveying system with minimal equipment wear and very low operating costs as a result of reduced friction in the conveying line.

Description: The Bruks air-supported belt conveyor offers an extremely smooth ride surface, eliminating the bumpiness characterized by traditional idler-supported belt conveyors. Therefore, material is discharged in the same condition as when it was loaded onto the belt. The Belt Conveyor is totally contained, preventing any material degradation and dust. Installs to date include Packaging Corporation of America (Counce, TN & Wallula, WA mills), and Barrette-Chapais (Quebec, Canada).

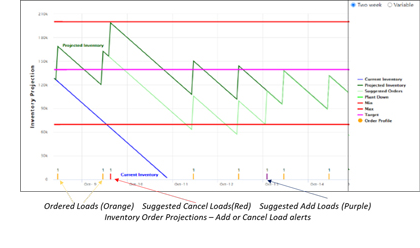

Customer Inventory Tracking and Prediction Service (CIT)

Customer Inventory Tracking and Prediction Service (CIT)

Entered By: Georgia-Pacific Chemicals LLC (GPC)

Date of First Use: August 2020

Benefit 1: Utilizes actual adhesive usage to predict and optimize order profiles easily.

Benefit 2: Reduced costs, downtime and quality issues. Ultimately, smoother operations.

Results: Saved tens of thousands of dollars in lost production and rushed or canceled order costs.

Description: CIT, a proprietary technology, tracks and predicts resin inventory, displaying it via a web-based desktop/mobile dashboard accessible only by a mill’s personnel. Each mill’s unique operational data is used to predict inventory levels based on demand and to place, move or cancel orders a needed for optimal efficiency.

Veneer Welder (Composer) Model: VWU-A70 with Veneer Clipping Scan Analyzer Model: GAIA VeCS

Veneer Welder (Composer) Model: VWU-A70 with Veneer Clipping Scan Analyzer Model: GAIA VeCS

Entered By: Hashimoto Denki Co., Ltd.

Date of First Use: April 2021

Benefit 1: Increased productivity by detecting the open and non-open defects in veneer by the line sensor camera with AI evaluation.

Benefit 2: Increased veneer quality by automatically clipping defects with higher precision by analysis from AI evaluation.

Results: Achieves higher level of composed veneer grading which increases the composed dry veneer quality and labor productivity.

Description: The VWU-A70, with the GAIA VeCS Scanner, is a high-quality dry veneer composing system with scan analyzer that increases labor productivity. Dry veneer is analyzed by the line sensor camera and grades its quality by the AI system and then composed according to the factory's production plan.

Z-PRESS - Edge gluing press for fast assembly bonding of solid wood laminations in cross laminated timber (CLT) production

Z-PRESS - Edge gluing press for fast assembly bonding of solid wood laminations in cross laminated timber (CLT) production

Entered By: LEDINEK ENGINEERING d.o.o.

Date of First Use: First half of 2020

Benefit 1: Allows fully automatic assembly of EGPs into CLT element prior to pressing (no disarray due to EGP instead of single boards).

Benefit 2: Allows fully automatic destacking of elements pressed at the same time (no between board glue percolation, no foil between elements).

Results: Omission of manual intervention during CLT element stacking assembly and as a result much shorter press times, more capacity, true full automation of the whole CLT production line, less operators. Omission of separation problems after pressing multiple CLT elements at once (no between board glue percolation). Easier interim storage and manipulation due to stacking possibilities of the EGPs, better dimensional tolerances through EGP in all dimension directions and accordingly less excess wood waste at trimming to final dimension on CNC routers and sanders. Better wood yield and improved visual surface quality of CLT elements due to closed micro fissures between boards in EGP.

Description: Edge gluing press for upgraded autonomy in Next Gen CLT productions by bonding otherwise loose board layers of a CLT element prior press-gluing into homogenous easy manipulable layers and elimination of all problems occurring due to loose boards which represent the “Achilles’ heel” to achieve full automation reliability of the existing CLT productions.

Raute R5 Panel Repair Station

Raute R5 Panel Repair Station

Entered By: Raute

Date of First Use: November 2021

Benefit 1: Process Automation

Benefit 2: Production efficiency and quality

Results: Up to 20% savings in panel repair material and significant labor savings.

Description: The newest development, Panel Repair Station R5, is the compact solution for automated panel repairing. This station fits into the same space as the traditional manual repair cell, doesn’t require special foundations and only needs one part-time operator. Most manual panel repair lines require two to eight personnel.

Smart Wax

Smart Wax

Entered By: Smartech

Date of First Use: 2018

Benefit 1: Better quality boards

Benefit 2: Huge savings

Results: Between 10% and 30% yearly savings on raw material

Description: SMARTECH’s pioneering SmartWax System transforms the way wax is used. The SmartWax System transforms the wax material into a wax suspension and provides unmatched cost savings for engineered wood manufacturing, while promoting improved product quality and superior control.

AddVantage Chop/Rip Defect Detection Using Artificial Intelligence (AI)

AddVantage Chop/Rip Defect Detection Using Artificial Intelligence (AI)

Entered By: USNR

Date of First Use: Q4 2020

Benefit 1: AI defecting is extremely accurate and consistent

Benefit 2: Multiple species change-overs with a click of a button

Results: Customer replaced six automated scan lines in under a year with six AddVantage systems running this new AI platform

Description: AddVantage uses four-sided, multi-spectral color vision with Deep Learning AI to locate, size and classify 100% of visual defects, bringing a much higher degree of accuracy and consistency to solutions. False defects are virtually eliminated by labeling the ground truth in the images. Startups are reduced from weeks to days.

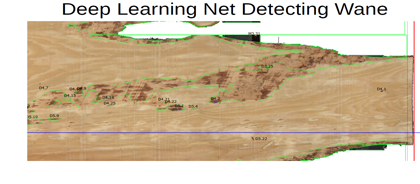

Wane Detection In Veneer Using Deep Neural Networks

Wane Detection In Veneer Using Deep Neural Networks

Entered By: USNR

Date of First Use: January 2021

Benefit 1: Finding cambium/wane areas without strong visual signature

Benefit 2: Reduces false wane detection

Results: Increase of 2.3 million bdft on grade

Description: Deep Learning is an advanced application of Deep Neural Networks (DNNs) used to identify defects in veneer. Wane/cambium defects are labeled and a DNN is trained, which is then applied in real time to green veneer. Optimizer decisions are then made to clip the veneer and send sheets to an appropriate sort or to the trash.