EWTA members are typically recognized at the APA Annual Meeting and EWTA Info Fair for innovative practices and excellence in service.

This year, we asked APA members to vote for the award winners via an electronic ballot. Following are the entries for the 2020 Innovation of the Year Award.

INNOVATION OF THE YEAR: ENTRY

INNOVATION OF THE YEAR: ENTRY

Precision Coat KP-12 Product Family

Entered By: Sansin

Date of First Use: 2012

Benefit 1: Dramatically improves topcoat performance for timbers, dimensional laminated lumber and engineered wood.

Benefit 2: Protects wood during manufacturing and construction processes.

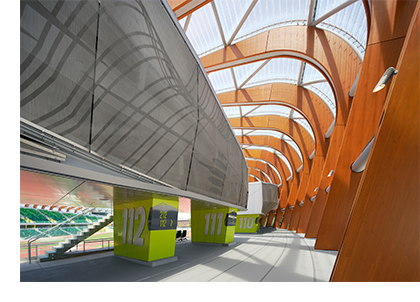

Results: 1) With KP-12 undercoat, the Quebec City Amphitheatre was protected from outdoor weathering during a lengthy construction timeline, but still able to be top coated with the final finish in situ. Still going strong since 2015. 2) The University of British Columbia Earth Systems Sciences Building has stood the test of time with KP-12. 8 years + on exterior in a natural color no less. One of the premier early mass timber examples.

Description: Penetrating aqueous low-VOC protective undercoating for structural wood, dimensional lumber, engineered

wood and mass timber subject to wet conditions. Designed for machine and HVLP airless application. Tintable formula

reduces swelling, wood rot, moisture absorption and protects against UV degradation and staining.

KP-12 is an outstanding penetrating protective undercoat for timbers, dimensional laminated lumber and engineered wood components like CLT that enhances dimensional stability and protects wood from UV degradation and moisture absorption. Using KP-12 dramatically improves topcoat performance, while also protecting wood during the manufacturing and construction process and reducing in situ preparation and top coat application costs. Because KP-12 is imperceptible, it is ideal for projects where beautiful clear or light wood tones are desired.

KP-12 is an outstanding penetrating protective undercoat for timbers, dimensional laminated lumber and engineered wood components like CLT that enhances dimensional stability and protects wood from UV degradation and moisture absorption. Using KP-12 dramatically improves topcoat performance, while also protecting wood during the manufacturing and construction process and reducing in situ preparation and top coat application costs. Because KP-12 is imperceptible, it is ideal for projects where beautiful clear or light wood tones are desired.

When used as part of an architectural coating system, KP-12 tinted can be used as the first coat. KP-12 is unique on the market for three major reasons:

- Non-solvent: lowest VOCs

- Recoatable:- allows for architects and builders to get mass timber to go from factory to finished product with same base system.

- Tintable: an undercoat (or sealer) that is part of the beautiful finish system - much more than protection. KP-12 is aqueous, low-VOC and available in a range of formulas to reduce swelling, wood rot, moisture absorption and protect against UV degradation.

INNOVATION OF THE YEAR: ENTRY

Chattermark Roughness System

Chattermark Roughness System

Entered By: Steinemann Technology USA, Inc.

Date of First Use: April 2020

Benefit 1: 100% quality control

Benefit 2: Operator notice that panel surface is trending toward B-grade/ Reporting of all panels processed

Results: Cost saving due to less B-grade panels

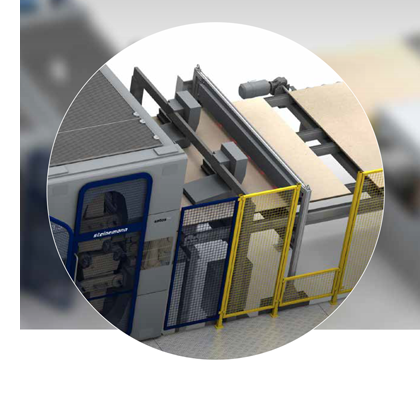

Description: The Chattermark Roughness Scanner (CRS) assesses whether the quality of the surface lies within a defined tolerance range, defined by the customer. Detects the surface quality of sanded wood-based panels. Continuous quality monitoring of designated roughness and chatter mark to maintain A grade panels.

- Surface Quality Detection System

- 100% online quality control

- Cost savings due to less B - quality panels

- Reporting process deviations via traffic light display system

- Quality report for fulfillment of delivery specifications

- Modular system design/ stand alone

- Compatible with BQC automation platform

- Application: Can be used on all Steinemann sanders as well as all 3rd parties sander