|

2025 Innovation of the Year Award Winner:

Edge-Damming System (Patent-Pend.)

Entered By: Con-Vey

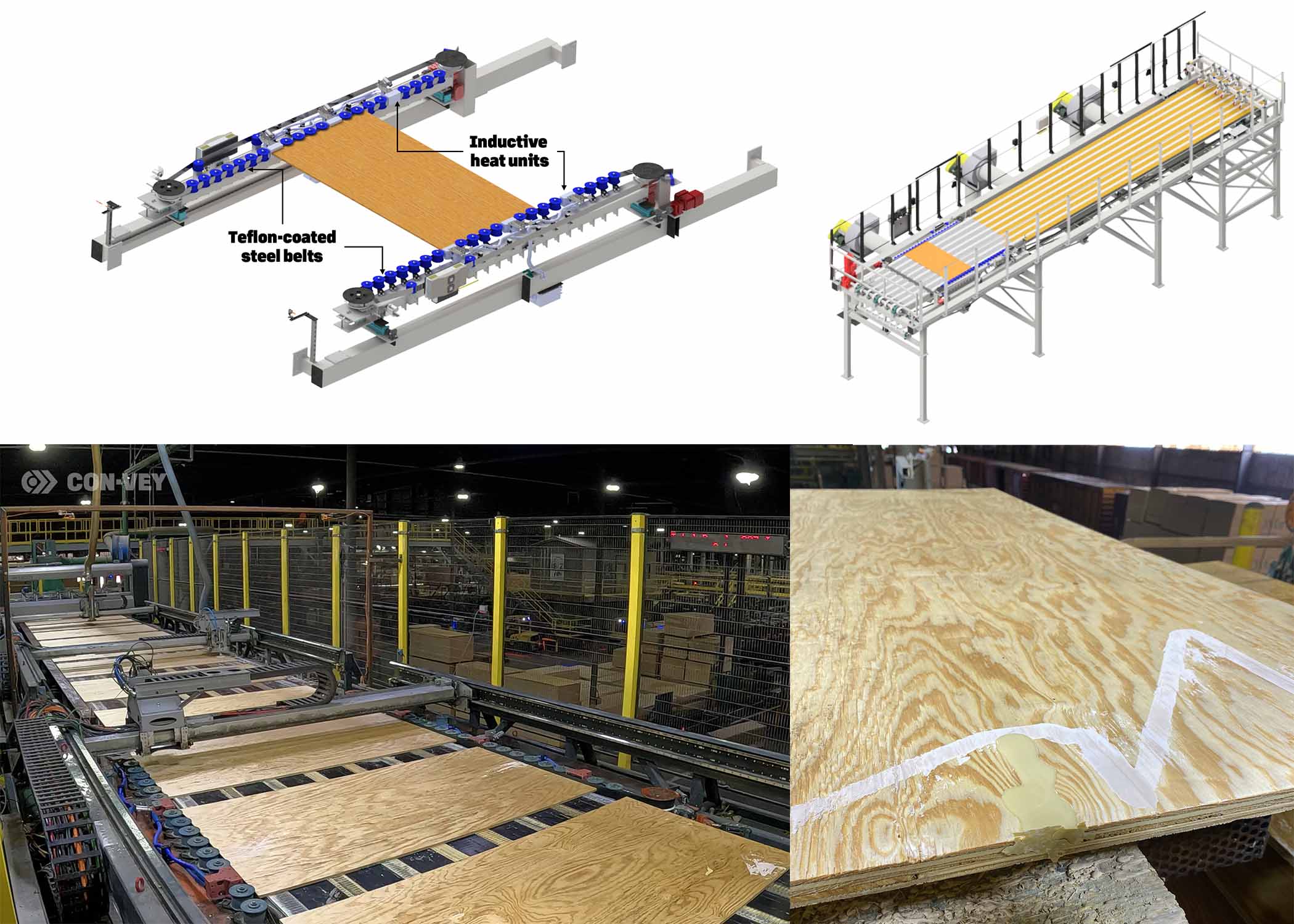

Description: Con-Vey’s patent-pending Edge-Damming System is a first-of-its-kind solution for in-line, automated repair of plywood panel defects. Designed for use post-trim, it seals and cures routed areas with precision—reducing labor, minimizing material waste, improving repair quality, maintaining continuous production flow, and offering a smarter, more flexible alternative to traditional repair methods.

Date of First Use: January 2024

Benefit 1: Enables precision edge repairs on trimmed plywood panels through in-line automation—eliminating manual bottlenecks and improving overall production efficiency.

Benefit 2: Reduces labor requirements and material waste by combining precise defect sealing with real-time, inductive heat curing.

Measurable results: RoyOMartin significantly reduced chemical usage, cut labor demands, and improved production flow. The automated system improved panel grade consistency and throughput, prompting a second system order shortly after launch.

Additional Details:

This innovation was developed by Con-Vey in collaboration with RoyOMartin to solve a unique challenge: how to repair dimensionally trimmed plywood panels without interrupting continuous production. The patent-pending system uses a Teflon-coated steel belt to dam routed defects and applies targeted inductive heat to initiate curing immediately—eliminating the need to pause before sanding or further processing. The result is a clean, durable, and consistent repair with minimal material waste.

“We’ve reduced costs on the line, we’ve reduced turnover, we’ve improved on grades, we’re meeting the panel throughput that we thought we would. The project has been a huge success. We’re very appreciative that Con-Vey took this risk with us. I wouldn’t hesitate to do any other project with their team.”

— Jeremy Burford, VP of Plywood, RoyOMartin

The success of this line led RoyOMartin to order a second system within months, demonstrating its real-world impact and ROI.

This solution also builds on several years of collaboration between Con-Vey and Argos Solutions, combining Argos’ cutting-edge defect recognition and repair technology with Con-Vey’s expertise in engineering and material handling. The result: a pioneering system that enables high-speed, in-line repair of plywood, supports safer, more sustainable production roles, and exemplifies the kind of innovation that continues to move the wood products industry forward.

For more on this project, go to https://con-vey.com/case-studies/revolutionary-edge-damming-system/ or watch a video of the line in action: https://youtu.be/u7Lr46y1syg?si=8fNglBo1ulOXaa5F.

|